Short Description:

Ringlock Scaffolding System is a direct plug-in pipe scaffolding system with self-lock function, it is the most popular scaffolding tools of the current construction market, it is also called Layher scaffolding (because of the basic theory of this scaffolding is invented by LAYHER company from Germany ), this scaffolding use Φ48*3.25mm,Q345B high tensile steel pipe as the main structure, the node points rosette plate is Φ122mm and 10mm thickness round plate with 8 holes pressed, then connected by 4 ledgers and 4 diagonal braces. Besides, it can be assembled with steel planks, transoms to form a fully functional Ringlock Scaffolding system.

Supply capacity: more than 30000T

Ringlock Scaffolding System is a direct plug-in pipe scaffolding system with self-lock function, it is the most popular scaffolding tools of the current construction market, it is also called Layher scaffolding (because of the basic theory of this scaffolding is invented by LAYHER company from Germany ), this scaffolding use Φ48*3.25mm,Q345B high tensile steel pipe as the main structure, the node points rosette plate is Φ122mm and 10mm thickness round plate with 8 holes pressed, then connected by 4 ledgers and 4 diagonal braces. Besides, it can be assembled with steel planks, transoms to form a fully functional Ringlock Scaffolding system.

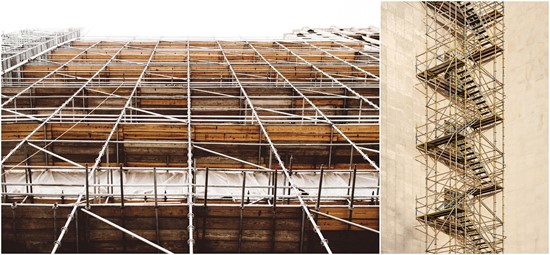

Ringlock Scaffolding System Introduction & Application

Usage

Ringlock Scaffolding are mainly used in high formwork, big span, cantilever structure, heavy support, deep foundation pit safety ladder projects and so on, like bridge project, tunnel project, factory, high water tower, power plant, processing plant, shipyard, and special factory support design, also can be used for concert stage, background stand, viewing stand, stairs system, concert stage construction, and contest audience area.

Versatility

Ringlock Scaffolding can form different sizes, shapes and different load-bearing capacities can be single/double scaffolding, support structure or support pole according to the construction instruments.

High Efficiency

Simple structure, easy to set up and demolish, avoid loss of screws work and small clamps, the speed to form connections is 5 times faster than normal scaffoldings, and a worker can finish all the assembling by a hammer, also it can be lifted as a whole structure to save time and shorten the schedule.

Heavy load-bearing capacities

The connection between vertical pipes is in the same axes center, the connection is within the same square, the connection is anti-bending, shear resistance and torque resistance, the material is Q345, stable structure, and heavy load capacities.

Safety and reliable

The design of connection considered the Gravity of its own, it makes the connection can be self-locked, the load will be transferred to vertical pipe through the clamp and the clamp is with high shear resistance(up to 199KN). The practice shows that the beam span within 15m and height within 12m, no matter single beam or multi continuous beam and form work structure house support system, the Ringlock Scaffolding safety and stability is better than Cuplock Scaffolding and Mason frame scaffolding.

Cost-effective

Lightweight, less amount, low maintenance, low cost, easy to erect and demolish, easy to deliver and stock.

High Quality

The Ringlock Scaffolding is automatically welded by machine, full-body by hot-dip galvanized, long life span.

Main Feature of Ringlock Scaffolding System

Versatility

he revolutionary node point-rosette provides up to 8 connections in one plane, allowing the system scaffolding highly adaptable for straight and curved structures, such as ship yards, power generation stations, petrochemical plants.Low Maintenance

The hot dip galvanized finish will greatly extend life of the procedure, no paint required, no more rust or corrosion, even they an be stored externally.

Size & Weight of NYALA Industrial Ringlock System

Ringlock Scaffolding System includes the basic structural parts Ringlock Standards/Verticals, Ringlock Ledgers, Diagonal Braces, Ringlock Truss Ledgers, Side Brackets, Base Collar, Intermediate Transoms, Lattice Girder, Jack Bases, Steel Planks, Steel Stairs and Wood Toe board, etc.

Ringlock Standards/Verticals

The Ringlock scaffolding Vertical is the key connection point for all other components of the Ringlock system, also is the most important part of the Ringlock scaffolding. Supported on the Base Jack or ground and the top end is connected to the upper Vertical by the inner joint, all linked with one another. It can be set up to the required height according to engineering requirements. Therefore, the Vertical’s material requires high hardness to guarantee the safety usually uses Q345 steel.

| Item No. | Product Name | Material | Size | Weight (kg) | Surface Treatment | |

|---|---|---|---|---|---|---|

| DA-R1001A | Ring Lock Vertical | Q345 | 48.3X3.25mm | 330mm | 2.29 | Hot-dip galvanized/Electro-galvanized |

| 500mm | 3.2 | |||||

| 1000mm | 5.7 | |||||

| 1500mm | 8.07 | |||||

| 2000mm | 10.45 | |||||

| 2500mm | 12.8 | |||||

| 3000mm | 15.3 | |||||

| 4000mm | 20.11 |

Ringlock Scaffolding Ledgers

The Ringlock Scaffolding Ledger is a component of the horizontal connection of the Ringlock scaffolding system. It is made of a steel pipe welded two ledger plugs at both ends with pins inserted into the Standard round rosette to erect the basis of the Ringlock scaffolding system. The ledger plug is produced by cast-steel using the wax mold.

| Item No. | Product Name | Material | Size | Weight (kg) | Surface Treatment | |

|---|---|---|---|---|---|---|

| DA-R1001B | Ring Lock Ledger | Q235 | 48.3X3.25mm | 390mm | 2.23 | Hot-dip galvanized/Electro-galvanized |

| 732mm | 3.42 | |||||

| 1088mm | 4.68 | |||||

| 1400mm | 5.67 | |||||

| 1572mm | 6.41 | |||||

| 2072mm | 8.2 | |||||

| 2572mm | 9.9 | |||||

| 3072mm | 11.71 |

Ringlock Diagonal Braces

The Ringlock scaffolding Diagonal Brace is manufactured as the Ringlock Ledger in the same way, except that the ends are welded with a diagonal plug. The Ringlock diagonal Braces are connected to adjacent Standard round rosette on different horizontal lines to form a triangle with the Vertical and the Ledger, using the triangular stability principle to ensure that the Ringlock Scaffolding System is more stable.