Full Description:

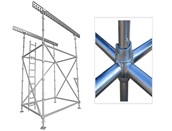

Original designed and invented by SGB Company with exceptional safety margins, the Cuplock Scaffolding System (also called CUPLOK) is a multifunctional modular steel pipe scaffolding system.Reasonable node joint structure, simple Manufacturing Process, easy and quick erection, especially widely construction application, which can fully meet the construction requirements of buildings such as houses, bridges, tunnels, chimneys, and water towers. Compared with the traditional type of Pipe & Couplers scaffold, the Cuplock System scaffolding has the broad development and application prospects all over the world.

Cuplock Scaffolding System Introduction & Application

Operation Principle

The Cuplock scaffolding is a kind of scaffolding with using a creative design” Cup” as node points. It is only needed to be welded fixed bottom cup and pre-installed movable Top Cup on the Vertical pole, inserted horizontal ledger with welded pins between two Cup node points without any scattered accessories such as bolts, nuts, and plugs. The Cup Node points are spaced on all standards at 500mm intervals to ensure that correct working lifts can be provided and handrails are positioned at the correct height. Four components are secured in one action ensuring the system is faster to erect than traditional methods.

System Cuplock Features

It has the advantages of rapid disassembly, labor-saving, stable and reliable structure, complete equipment, strong versatility, large bearing capacity, safe and reliable, easy to process, not easy to lose, easy to manage, easy to transport, and widely used. It has greatly enhanced the work effectiveness

Surface Treatment & Application Life

According to the requirement clients, our company NYALA Industrial SCAFFOLD can supply surface treatment of Painting, Powder Coated, Electro-Galvanized, and Hot-dip Galvanized.

Painting service life: 1 year in the dry construction environment

Powder Coated service life: 2-3 years in the dry construction environment

Electro-Galvanized service life: 2-3 years in the dry construction environment

Hot-dip galvanized service life: at least 10 years in the dry construction environment

Note: Above the service life only refers to the surface treatment of scaffoldings, not considering the components’ damage, loss, deformation, etc.

Cuplock Scaffolding System Market.

At present, the main markets of Cuplock Scaffolding System are in America, Europe(just like UK), Northern Africa (Sudan, Algeria, Kenya), Middle East (United Arab Emirates, Saudi Arabia, Qatar), Singapore.

Main Feature of Cuplock System Scaffolding

High bearing capacity

The pole connection is a coaxial socket, the crossbar is connected with the Vertical by the joint of the bowl cup, and the joint has reliable bending, shearing and torsion resistance. Moreover, the axial line of each member intersects at one point, and the node is in the plane of the frame. Therefore, the CUPLOCK structure is stable and reliable, and the bearing capacity is high. (The overall bearing capacity is increased, which is about 15% higher than the fastener-type steel scaffolding in the same situation. Quick erection, all Ringlock Scaffolds are pre-measured and just a hammer is required when erection

Not easy to lose

These type of Cuplock scaffold has no loose fittings, eliminating bolting and minimizing the loss of accessories. Because of forged top cup and ledger blade accessories, these components are resistant to hitting. No special maintenance or repair is required.

Multi-function

According to the specific construction requirements, it can form single and double-row scaffolds, support frames, support columns, material lifting frames, climbing scaffolds, cantilever frames and other functional construction equipment's with different frame size, shape and carrying capacity. It can also be used for building sheds, sheds, lighthouses, bridges, oilfield construction and other buildings. Particularly suitable for erecting curved scaffolding and heavy-duty support.

Components’ Size & Weight of NYALA Industrial Cuplock System

The basic structural components of the Cuplock scaffolding system are Vertical Poles(Standards), Horizontal Ledgers, Diagonal Braces, Jack Bases, Steel Planks, etc. The auxiliary accessories include Intermediate Transom, Inside Intermediate Transoms, Omega Transom, Hop-Up Bracket, Omega Hop-Up Bracket, Steel Ladder, Stairways, etc.

Cuplock Standards/Verticals

These items from the Vertical Members of the scaffolding are made from Q345B high tensile steel tube with a size Diameter 48.3mm X thickness 3.25mm. The standard includes a fixed bottom cup which is welded at 500mm intervals, with a movable top cup that can secure up to four components.

These cups are the fixing node points for the horizontal ledgers, hop-up brackets, transoms, and ancillary items. At the top of the standard usually comes with Spigot that allows the further connection with other standards.

At the bottom of the standard, there is a corresponding drilled hole to allow below standards to be bolted together.

| Grade | Delivery Condition | Specification | Size |

|---|---|---|---|

|

Hot Rolled, Annealed, Pickled, Cold draw, Sandblast | ASTM A276/A276M/A484/484M |

|

Cuplock Horizontals Ledgers These are horizontal members that from the ledgers of the Cuplock system.They are made of diameter 48.3mmX3.0mm thickness steel tubes, which are welded forged blades both ends so that can be inserted into the Cup nodes of the standards completely.As the basic parts of the Cuplock scaffolding system, it’s simple, easy and quick to assemble. It can also be served as a guardrail in staircase towers.Sizes are the following standard sizes, also can be designed and customized as requirements.

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

|---|---|---|---|---|---|

| DA-C1001B | Cup Lock Ledger | 48.3X3.0mm 600mm | 2.47 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 48.3X3.0mm 900mm | 3.55 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1000mm | 3.92 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1200mm | 4.28 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1250mm | 4.83 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1300mm | 5.01 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1500mm | 5.73 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1600mm | 6.06 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 1800mm | 6.81 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 2000mm | 7.54 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | ||

| 48.3X3.0mm 2500mm | 9.55 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized |

Diagonal Braces

The NYALA Industrial Cuplock Diagonal Brace has three styles to form the oblique connection systems. The brace comes in different lengths to suit combined ledger sizes and standard heights.

Braces end can be made usual swivel forged blade or half coupler’s and snap’s which all allowed to be connected on Standard.

Three styles:

Swivel Blade Face Brace;

Swivel Clamp Brace;

Snap to Snap Brace;

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

|---|---|---|---|---|---|

| DA-C1001C | Swivel Blade Braces | 48.3X3.2mm 1.8X1.5 M | 8.25 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 1.8X2.0 M | 9.31 | Q235 | |||

| 2.5X1.5 M | 9.99 | Q235 | |||

| 2.5X2.0 M | 10.86 | Q235 | |||

| 3.0X2.0 M | 12.10 | Q235 | |||

| Swivel Clamp Braces | 48.3X3.2mm 10’X2.0 M | 15.9 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | |

| 9’X2.0 M | 15.0 | Q235 | |||

| 8’X2.0 M | 14.0 | Q235 | |||

| 7’X2.0 M | 13.2 | Q235 | |||

| 5’X2.0 M | 11.6 | Q235 | |||

| 2.5MX2.0 M | 14.2 | Q235 | |||

| 1.8MX2.0 M | 12.3 | Q235 | |||

| 1.6MX2.0 M | 11.8 | Q235 | |||

| Snap to Snap Brace | 48.3X3.2mm 10’X2.0 M | 16.2 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized | |

| 9’X2.0 M | 15.3 | Q235 | |||

| 8’X2.0 M | 14.3 | Q235 | |||

| 7’X2.0 M | 13.5 | Q235 | |||

| 5’X2.0 M | 11.9 | Q235 | |||

| 2.5MX2.0 M | 14.5 | Q235 | |||

| 1.8MX2.0 M | 12.6 | Q235 | |||

| 1,6MX2.0 M | 12.1 | Q235 |

Cuplock Hop-Up Bracket: NYALA Industrial Cuplock Hop-Up Brackets are designed to increase the width of the working platform from five boards to eight boards wide, by supporting additional boards beyond the inside face of the scaffold. They incorporate a cup to locate an additional inside ledger, which links adjacent hop-up brackets to prevent movement, while also supporting intermediate transoms. There is also a location point for a handrail post if required.

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

| DA-C1001D | Cuplock Hop Up Bracket | 291mm | 1.5 | Q235 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 565mm | 6.6 | ||||

| 795mm | 7.9 |

Intermediate Transom

The Cuplock Intermediate Transom is designed to provide safe mid-bay support for scaffold boards. One end is provided with an integral locking device to prevent movement along the horizontal during use. Available in Hot Dip Galvanized Steel Tube 48.3X3.0mm

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

| DA-C1001E | Cuplock Intermediate Transom 48.3X3.0mm | 565mm | 3.85 | Q345 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 795mm | 4.70 | ||||

| 1300mm | 6.50 | ||||

| 1800mm | 8.31 |

Cuplock Steel Planks

The NYALA Industrial Cuplock Steel Planks are made by Pre-galvanized decks with welding hooks on the end. Simple but convenient, more light but strong. Also available in Hot Dip Galvanized.

The Cuplock System scaffolding steel planks’ lengths must be matched up with Cuplock ledgers. There are always hooks on both ends of steel planks for Cuplock Scaffolding, while scaffold steel battens without hooks can put on Cuplock omega transom and Omega brackets.NYALA Industrial Cuplock steel planks are compatible with all Cuplock scaffolding systems worldwide.

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

| DA-C1001F | Cuplock Steel Planks | 910mm | 7.68 | Q345 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 1220mm | 9.73 |

Inside Intermediate Transoms

Extend beyond ledgers providing support to board when inside boards are required. Available In Hot Dip Galvanized Steel Tube 48.3X3.0mm

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

| DA-C1001G | Cuplock Inside Intermediate Transoms 48.3X3.0mm | 1300mm | 8.28 | Q345 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 1620mm | 9.5 | ||||

| 1900mm | 10.2 | ||||

| 2170mm | 11.2 |

Omega Transoms

NYALA Industrial Omega Transoms specially designed T-Section 60X40mm provides a firm location for steel stage and Cuplock battens.Blades end inserted into the lower cups between the verticals to form the lateral spacing and to support the platform battens.

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

| DA-C1001H | Cuplock Omega Transoms | 800mm | 4.97 | Q345 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 1300mm | 8.0 | ||||

| 1800mm | 11.05 |

Omega Hop Up Bracket

NYALA Industrial Omega Hop Up Brackets are designed to increase the overall working platform from five battens to seven or eight battens wide, by supporting additional battens beyond the inside face of the scaffolding.They incorporate a cup to locate an additional inside ledger, which links adjacent hop-up brackets, to prevent moments.There is also a location point for a handrail post if required.

| Item No. | Product Name | Size | Weight (kg) | Material | Surface Treatment |

| DA-C1001I | Cuplock Omega Hop Up Bracket | 291mm | 2.13 | Q345 | Hot-Dip Galvanized/Paint/Electro-galvanized |

| 565mm | 7.85 | ||||

| 795mm | 9.72 |

Cuplock Scaffolding Construction Applications